Video

Details

Updated on March 25, 2022 at 6:33 pm-

Machine ID:

ML-18861 -

Category:

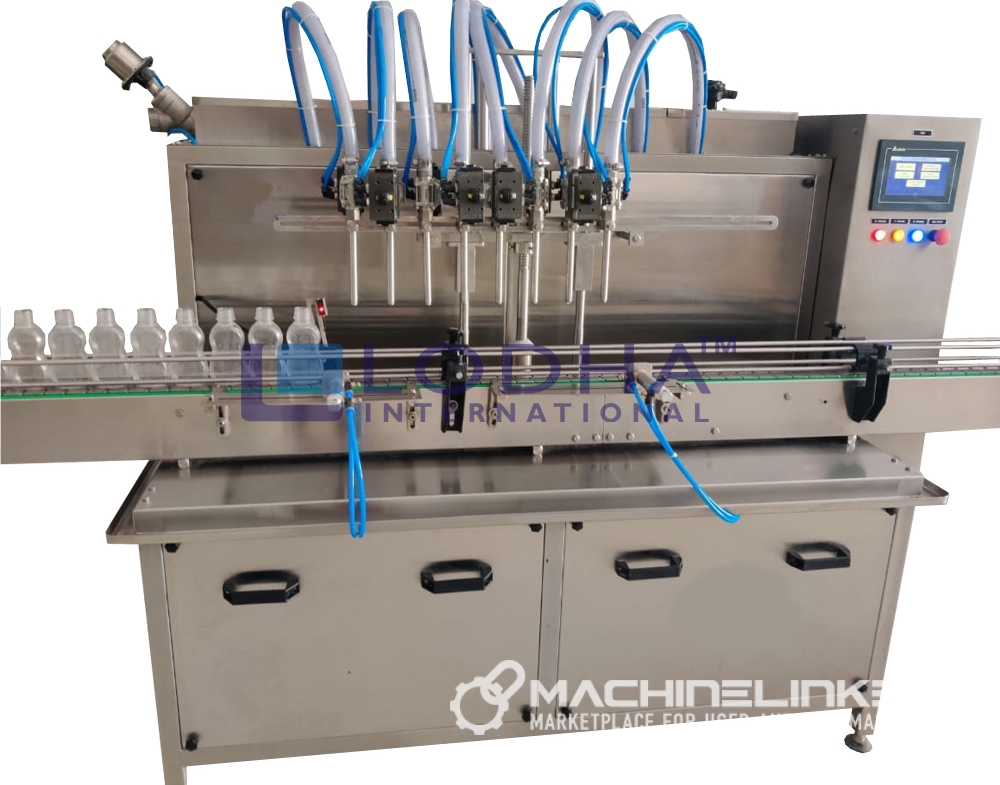

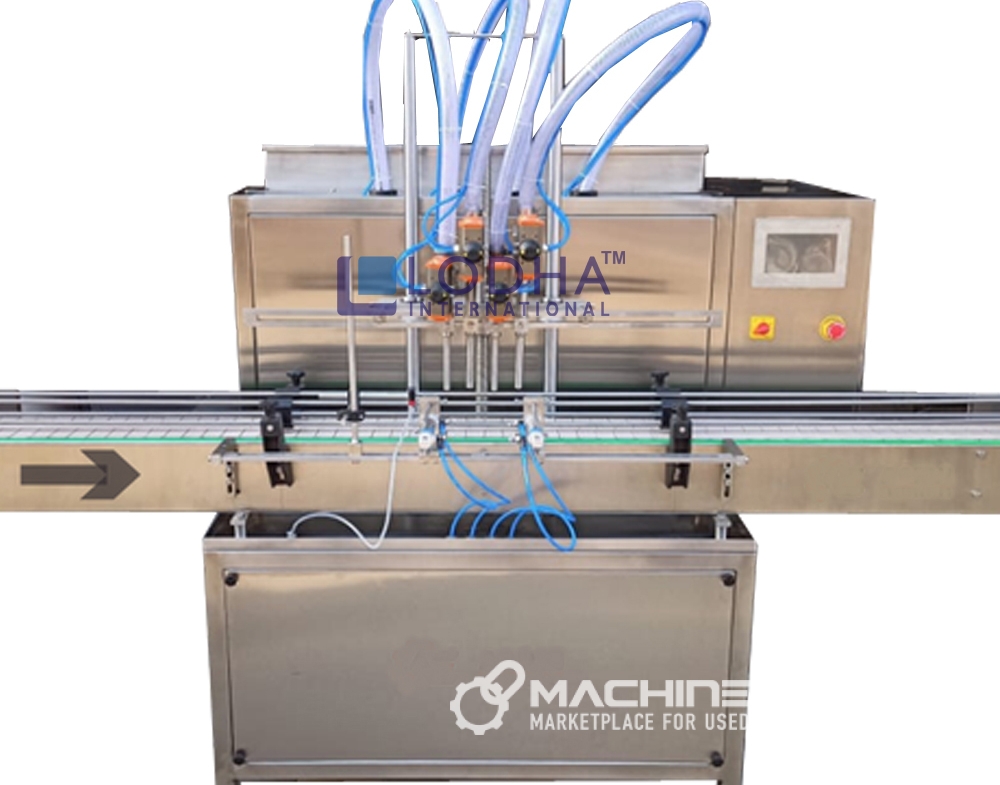

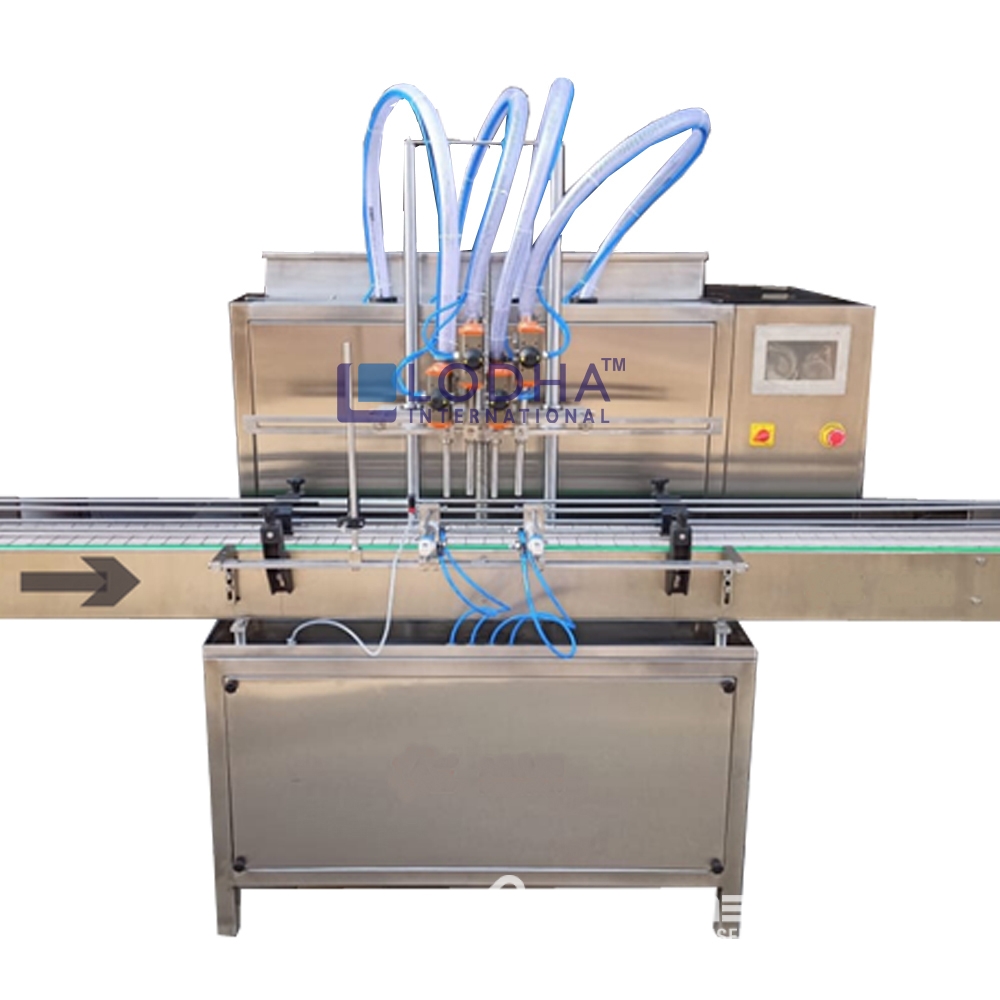

Other chemical-pharmaceutical equipment - Machine type:

Filling Machine - Manufacturer:

LODHA - Model:

Servo Automatic Liquid Filling Machine -

Year of manufacture:

2022 -

Condition:

New - Detailed condition:

Brand-new (new) - Rental?:

No

Description

Automatic Servo Liquid Filling Machine: Containers moving on SS Slat conveyor, feed below the filling nozzles through a settable twin pneumatically operated stopper system. The twin pneumatically operated stopper system and reciprocating nozzles can precisely match for centring of container below nozzles, to avoid spillage of liquid on container. To minimize foaming adjustable nozzle will reciprocate according to filling dose, nozzle will go upwards from bottom level of bottle towards neck during filling. The Digital filling system arrangement is standard features of the machine. The motor for filling is servo drive and conveyor drive are AC Motor with synchronized variable AC Frequency Drive. PLC Controller provided to set fill volume, speed of conveyor and set fill timing this means fill size can be easily set.

Special Features:

Accuracy ± 0.8 % or 0.5Gram in single doze (Whichever is higher). No change parts require. Individual volume control for all syringes. Different speeds can be set, depending on fill volume and foaming nature of material. Body covered with SS sheet. All contact parts silicon tubing and S.S.316. A unit to fill variety of liquid and can be used for various type of containers. No dropping or last drop problem No bottle no filling system. 60 Litre Storage/Holding Tank fitted with Machine. Facility provided for the fine tuning of the volume. Inbuilt protection against over current, voltage fluctuation, short circuit in AC frequency Drive. Ideal for aseptic, sheer sensitive, viscous, and corrosive liquids also.Machine location

Open on Google Maps- Address 98, Gajanan Industrial Hub-2,Behind Matrix Plaza, GIDC Vatva, Ahmedabad-382445, Gujrat, India

- City Ahmedabad

- Zip/Postal code 382445

- Country India