Details

Updated on May 22, 2024 at 4:51 pm-

Machine ID:

ML-26065 -

Category:

Other chemical-pharmaceutical equipment - Machine type:

Filling + Closing - Manufacturer:

OPTIMA - Model:

CFR2-2 -

Year of manufacture:

2019 -

Condition:

Used - Detailed condition:

As good as new (ex-display) - Rental?:

No

Description

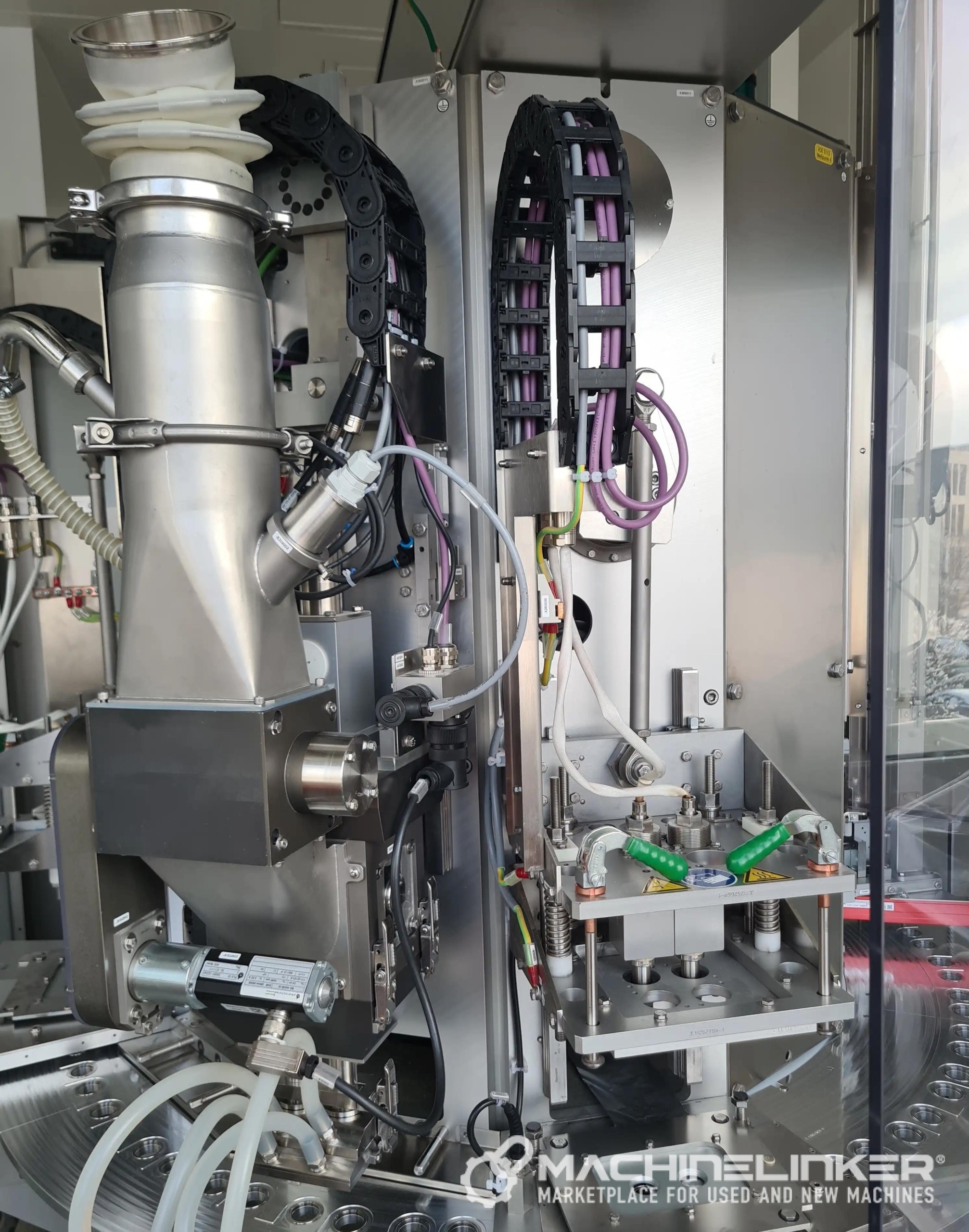

OPTIMA CLOSING AND FILLING MACHINE, MODEL CFR2-2

Year of construction: 2019

OPTIMA Type CFR2-2 is pre-configured for compatible capsules. Can be ordered with our new Starter-Kit; the key advantage is that production can begin immediately. Modular machine design for maximum flexibility for future adaptations of products, packaging or functions.

Technical data

Basic measurements approx. (LxWxH): 2,100 mm x 2,100 mm x 2,500 mm Working stations: max. 12 Output: between 100 and 220 caps./min. Dosing range: between 1 g and 18 g Format range: between 30 mm and 60 mm Capsule height: max. 40 mm Capsule width: between 30 mm and 60 mm FillingFilling process in protective gas for reduced oxygen contents in the packaging. Suction nozzles or suction bell for reduced dust emergence during filling. Filling and closing systems coordinated to the product

Dosing/Weighing100% gross weighing. Identifying and adjusting for fluctuations in the bulk weight. Volumetric dosing with auger filler. High-precision positioning for constant filling weight/volume

CapsulesCapsule destacking or capsule feed as bulk goods via fully automatic sorting and optional storage bin. Cycled capsule transport. Raising the capsule when filling to prevent dust accumulation. Maximizing performance due to double-track capsule transport with the same number of filling positions

DriveDrive via wear-free servomotors

HandlingSimple, clearly arranged operation and graphic display of the machine status on the HMI

DesignGood visibility and accessibility. Integrated separation for reject product and/or production patterns. Compact design with integrated control cabinet. Secure and sturdy mechanical system

Machine location

Open on Google Maps- Address Via Don L. Guanella 1/E

- City Bologna

- Zip/Postal code 40141

- Country Italy