Video

Details

Updated on April 17, 2025 at 6:42 am-

Machine ID:

ML-25841 -

Category:

Stirring and mixing equipment - Machine type:

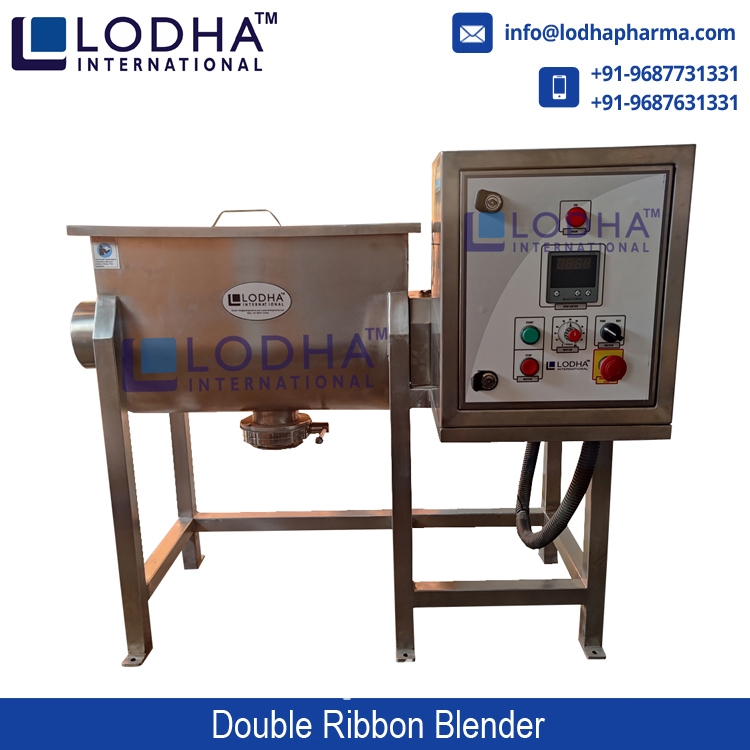

Ribbon Blender LI-RB 1 - Manufacturer:

LODHA - Model:

LI-RB 1 -

Year of manufacture:

2025 -

Condition:

New - Detailed condition:

Brand-new (new) - Rental?:

No - Volume capacity :

100 Liters - Mixing speed :

1440 RPM - Double jacketed :

Yes - Type:

Ribbon and paddle - Motor Power :

2.23714 kW - S/ steel type :

SS 316, SS 304 - Length x width x height :

1000.0 × 800.0 × 1000.0 - Weight:

600 KG

Description

The Ribbon Blender Model LI-RB is a tiny model that is frequently used in the pharmaceutical, nutraceutical, cosmetic, chemical, and food industries. It is a light-duty, compact blender that is specifically developed to achieve the conventional technique of blending powder components that have been pre-processed, such as dried granules and pre-sieved powders. It is a low-shear mixer that is perfect for solid-to-solid mixing. Solid-liquid mixing can also be accomplished when strong shearing power is not required. It occupies less headroom area for large volume mixing compared to Double Cone, ’V’ Blenders, etc.

Special features:

Available in two shapes: U and W.

U: For Low to Medium Volume Capacity (Single shaft).

W: Large to Mega Volume Capacity (double shaft).

Batch size is based on 65% of the blender volume.

All contact components are made of 304 stainless steel.

Mount bearings on lights outside the mixing zone to prevent cross-contamination.

The blender has a charging port installed on top.

Reduced material handling with side discharge of processed products.

Monoblock design prevents cross-contamination.

meets all CGMP standards.

Air purge side entry seals for improved cross-contamination control.

The continuous ribbon design ensures complete discharge of the finished product.

Fine-tune Shear energy at various phases of blending with a variable-frequency drive.

Belt-driven power transmission for quieter operation and reduced maintenance.

Top-mounted charging port and side discharge configuration save material handling and ensure total containment.

Bearings positioned on lights outside the mixing zone prevent cross-contamination.

Use a paddle-style agitator instead of a ribbon to blend fragile materials.

Capacity ranges from 50 to 2500 kg.

Applications include pharmaceuticals, nutraceuticals, chemicals, cosmetics, and foods.

Machine location

Open on Google Maps- Address 98, Gajanan Industrial Hub -2 Behind Matrix Plaza, GIDC VATVA, Vinzol,

- City Ahmedabad

- Zip/Postal code 382445

- Country India