Details

Updated on April 4, 2024 at 9:13 pm-

Machine ID:

ML-25766 -

Category:

Digital printers - Machine type:

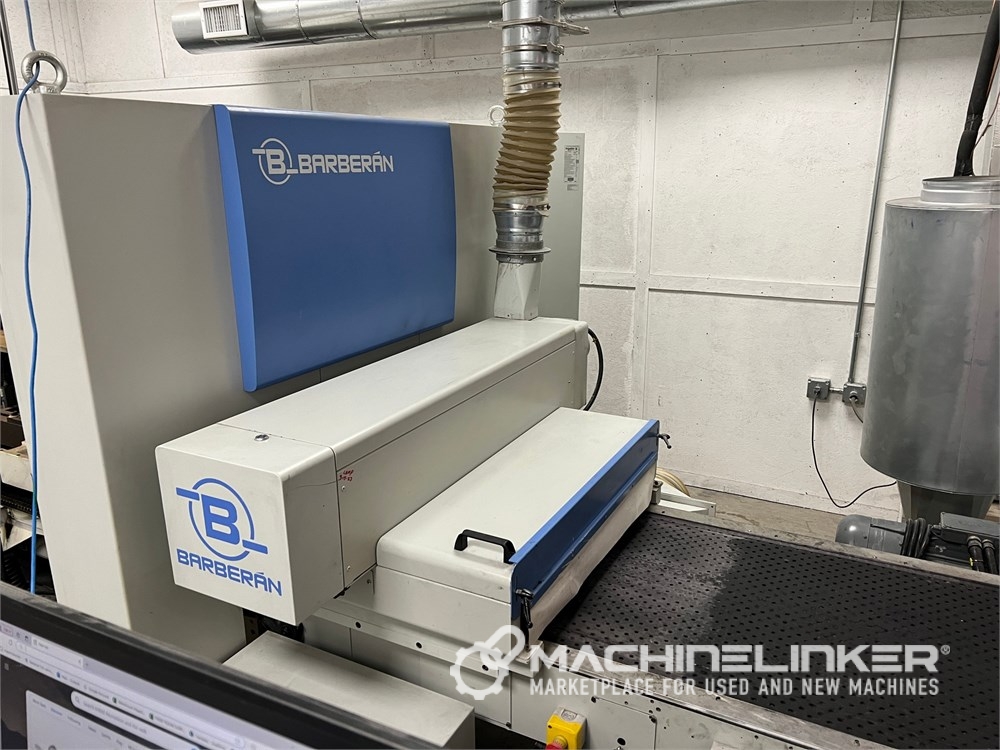

Digital printing presses - Manufacturer:

Barberan - Model:

Jet Master 630 Single Pass Digital Printer -

Year of manufacture:

2021 -

Condition:

Used - Detailed condition:

Excellent (used) - Rental?:

No

Description

New concept of Single Pass Digital printing

The Barberan Jetmaster printers are a new concept based on Single-Pass printing technology of printing digital images on multiple substrates at an industrial level. Barberán S.A has a long history in conventional printing technologies and is one of the pioneers in Single Pass Digital printing application techniques, developing its own mechanics, electronics and software. Thanks to the experience of Barberan in the surface treatment, we are able to achieve an optimum printing quality on any type of substrate. The inks used in the Jetmaster printers are 100% UV inks which guarantees a stable process achieving a high quality print.

Flexibility and better cost-effectiveness. Advantages of Digital Printing technology Personalization and customization of designs unmatched by analogue processes Short to medium print runs with no extra costs Quicker response time to market Faster proof cycle Variable printing More options of substrates to print on due to its non-contact printing technology Elimination of inventory Just-in-time delivery

In short you will be able to offer your customers with more options and provide them with better service

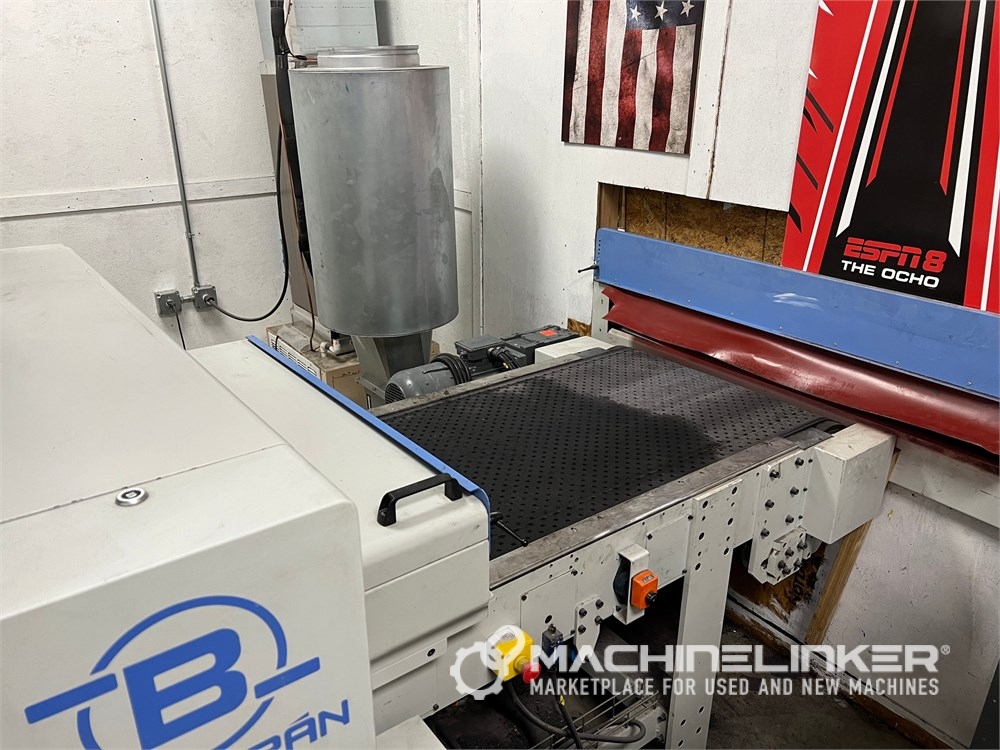

The Barberan Jetmaster is a single pass digital printing machine at industrial level printing on wood, paper, MDF,glass, PVC, flooring and other materials with flat surface. The Jetmaster can be supplied as stand alone machine or integrated into a complete production line where panels receive a base coat , are sanded , printed and finished with a top coat of high gloss or mat.

The Barberan printing technology is based on the CMYK technology, the 4 groups of top printing heads are placed on a heavily build frame where the panels are transported by means of a holed vacuum belt with bottom vacuum system which ensures that the panels are kept in their position allowing a perfect register print. A laser device measures constantly the substrates thickness with a 0,1 mm. accuracy and automatically regulates the height of the printing groups.

The machine is equipped with a user friendly design system which enables the machine operator to convert automatically the more common formats of the digital images such as Tiff, Ai , PDF, JPG into the operational format of the Jetmaster, and at the same time manage with high precision the colors during the different stages of the design up to the final print . This reduces drastically the time spend in adjusting the print images. A graphic designer can simulate perfectly on the screen of a computer and desktop printer the final result before the actual design is passed to production on the Jetmaster . Previously the design can be optimized or altered in “photo-shop”according to the specific demands of your customers converting the process in an easy , fast and flexible way of printing and therewith gaining many benefits for you and your customers. The Barberan printing technology is based on the concept “ less is more “ . By optimizing the drop size and the image processing we obtain printing results with a powerful chrome and bright colors with the minimum amount of ink. The Jetmaster controls at all times the ink costs and production process. The Jetmaster offers a high printing quality on almost any kind of substrate at a max production speed of 55 m/min with the possibility of instantaneous design changes during the printing process from one panel to the next or even optionally print multiple panels simultaneously.

Inkjet printing machine for widths up to 630 mm

Because of the great accurate register print the Jetmaster is capable of reproducing one big single design onto smaller slabs without having to worry about the exact accurate positioning of the images on each individual slab. They will fit perfectly.

Machine location

Open on Google Maps- Address 6660 Taylor Road, Unit 108

- City Punta Gorda

- Zip/Postal code 33950

- Country United States