Video

Details

Updated on March 10, 2022 at 3:07 pm-

Machine ID:

ML-17438 -

Category:

Screen printing machines - Machine type:

Semiautomatic (clamshell) screen printing machine - Manufacturer:

Mismatic - Model:

Eco Matic 819 -

Year of manufacture:

2022 -

Condition:

New - Detailed condition:

Brand-new (new) - Rental?:

No

Description

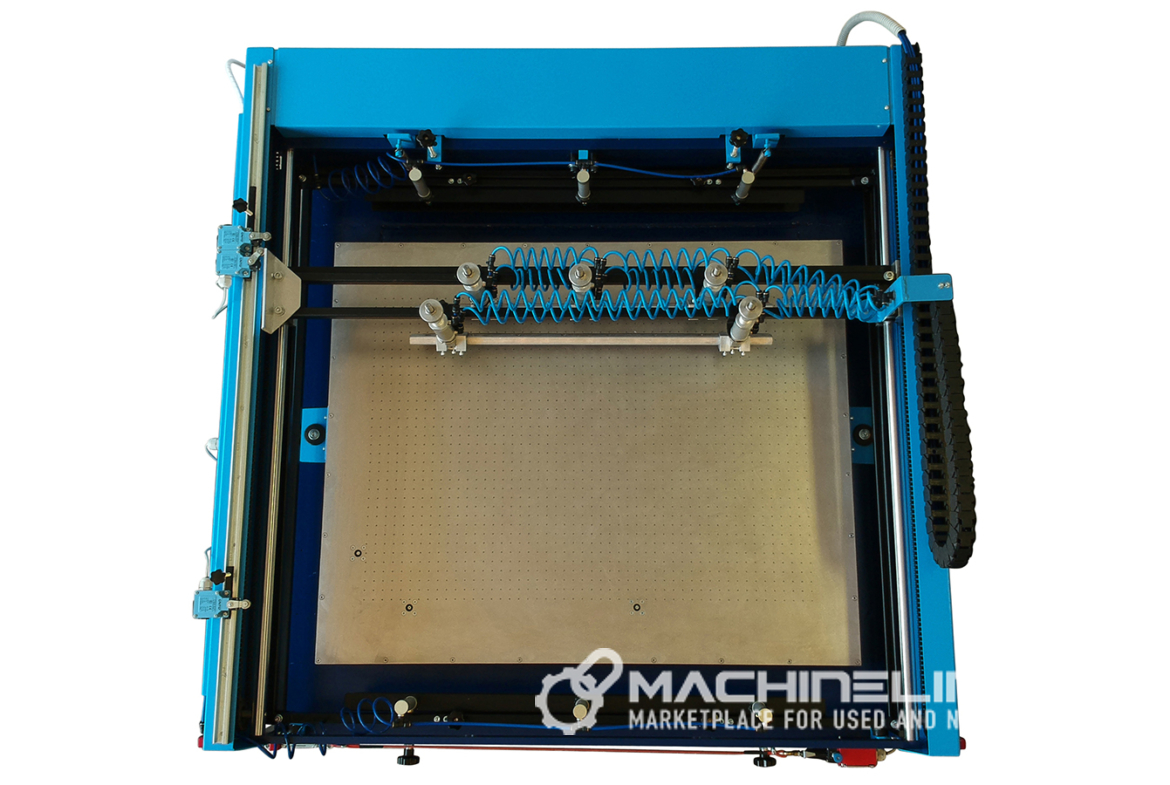

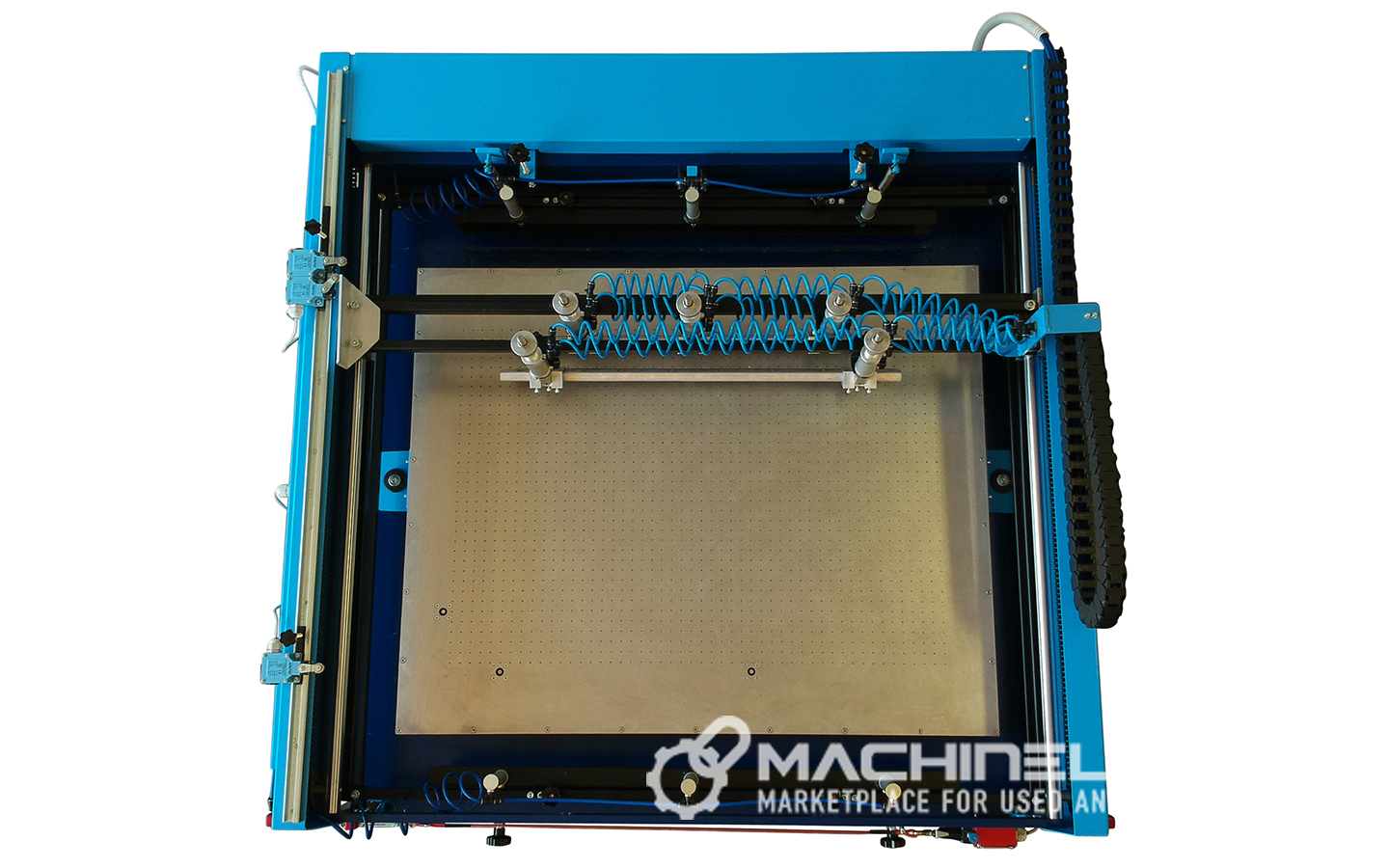

The screen printing machine model ECO MATIC 819 has been designed and built to print paper, cardboard and plastic sheets, wooden panels, metal and glass sheets.

Automatic ink recovery system

Screen printing machines have a flaw: after some prints, the ink slips at the bottom of the screen and the user is forced to bring it back with a spatula. Thanks to the automatic ink recovery system, the user no longer must do this operation.

During printing, the squeegee and scraper move between two limit switches. When the system is activated, the squeegee and scraper make a longer stroke in order to get the ink that has slipped at the bottom of the screen and bring it back for subsequent prints.

The user can choose whether to activate the system after each print, after a certain number of prints or to deactivate it (this in case the length of the screen does not allow the use of the system).

Full cover printing? No problem!

The machine is equipped with the Synchroprint system: the screen gradually lifts from the printing table as the squeegee moves forward.

This system is excellent for most jobs, but it is not enough when printing full cover jobs, that is, when you must print the whole surface of the material.

For optimal results when printing full cover jobs, the printing head must not open immediately after printing, but wait for a moment, so that the screen fabric can detach completely from the material just printed.

From the machine control panel, it is possible to set the required waiting time before the printing head opens. In this way, printing full cover jobs is no longer a problem, but it is a piece of cake!

Printing sizes: 36 x 51 cm | 51 x 76 cm | 71 x 106 cm | 81 x 131 cm | 101 x 141 cm

Documents

Machine location

Open on Google Maps- Address Via A. Marino 15/17

- City Pieve Emanuele (Milan)

- Zip/Postal code 20072

- Country Italy