Details

Updated on February 16, 2024 at 8:34 am-

Machine ID:

ML-25503 -

Category:

Other chemical-pharmaceutical equipment - Machine type:

Fermenter - Manufacturer:

TECNINOX - Model:

Fermenter -

Year of manufacture:

2015 -

Condition:

Used - Detailed condition:

As good as new (ex-display) - Rental?:

No

Description

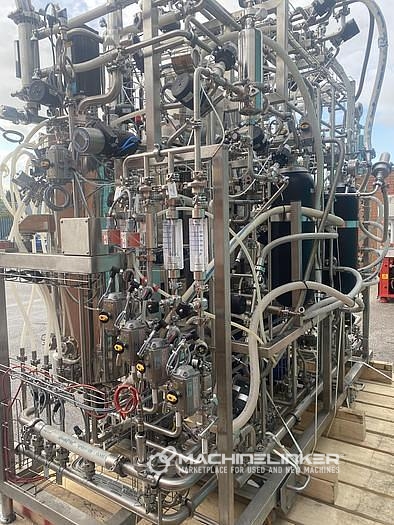

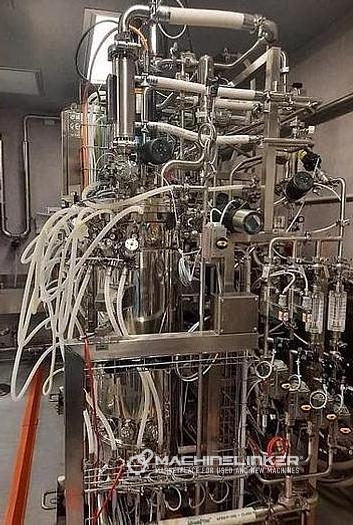

TECNinox fermenter/bioreactor

Year of construction: 2015

Suitable for R&D, small batch production, pilot plant. Box of manuals included.

Characteristics:

Fermenter head without sharp edges to improve cleaning, GMP gasket; with TC connections of various sizes (3/4, ½, 1), usable for additions, feeding, inoculation, etc. Fermenter geometry: 3:1 Operational pressure range: -0.01 to 3. 00 bar g Double mechanical seal Impellers 3 Rushton / 3 Pitched Blade Configurable motor speed: 50-1500 rpm Motor position: overhead motor shaft, as close as possible to sparger and bottom Toroidal sparger with possibility of coupling and uncoupling Exhaust gas condenser Integrated CIP system Working volume for 36L bioreactor: 20L, Minimum working volume 7.5L (positioning holder for probes) Working volume for 74L bioreactor: 50L, dependent on position of last impellerExhaust gas management: double exhaust gas line after the outlet filter (the gas line must divide into two branches: one direct to the spent gas analysis system (airnova) and the other to the drain/waste)

Inlet air from above and from the sparger, with flowmeter

Aeration: 0 to 2. 5 VVM

O2 inlet: 0 to 2.5 VVM, O2 inlet from above and from the sparger, with flowmeter

N2 inlet: 0 to 1 VVM, N2 inlet from above and from the sparger, with flowmeter

CO2 inlet: 0 to 1 VVM, CO2 inlet from above and from the sparger, with flowmeter

Head pressure adjustment: automatic Fixed speed pump with remote control Bottom valve filter Variable speed pumps, two bottom valvesIntegrity test: integrated housing to perform in situ integrity test

Loading soil hole for manual loading

Fixed speed Peristaltic pumping, position adjacent to bioreactor pH, for control of acid/ base, CO2

Feeding base inlet via Sacova valve with ingold control

Requirements:

Electricity: 380v, 50Hz

Steam feed: 3 – 9 bar

Clean steam: 3 bar g

Purified water

Compressed air: 8 bar g

Refrigerated water: 9 – 12 deg C

Nitrogen: 8 bar

Oxygen: 12 bar

CO2: 8 bar

Softened water

Drainage and discharge

Machine location

Open on Google Maps- Address Via Don L. Guanella 1/E

- City Bologna

- Zip/Postal code 40141

- Country Italy