Details

Updated on November 11, 2023 at 11:56 am-

Machine ID:

ML-24130 -

Category:

Other chemical-pharmaceutical equipment - Machine type:

Tubes Filler - Manufacturer:

IWKA - Model:

TFS 20 -

Year of manufacture:

1991 -

Condition:

Used - Detailed condition:

As good as new (ex-display) - Rental?:

No

Description

This unit is a filling and closing machine for metallic, aluminium tubes.

The construction principles, materials used and innovative concepts guarantee maximum productivity, user friendliness and quality, making this machine an ideal solution for the pharmaceutical and the cosmetic market. Special consideration was given to a rapid change over to different tube sizes and consistency of filling product. The in-built flexibility makes it the ideal machine for use in research and development.

Easy to use machine with excellent access for cleaning and maintenance.

Technical data:

Length mm 1825

Width mm 1115

Height mm 2150

Net weight Kg 2200

Production characteristics:

Tube diam. min-max 10-52 mm

Tube length min-max 52-250 mm

Dosage min-max 2,5-500 ml

Production capacity 40-120 tubes/min

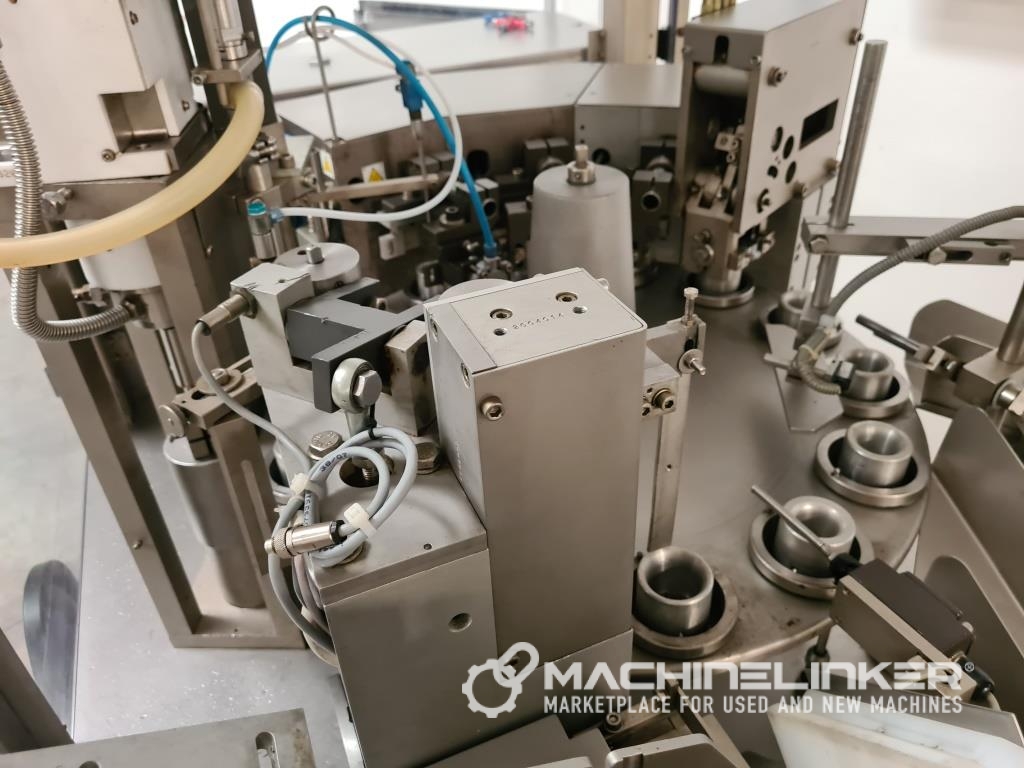

Automatic tube filling machine equipped with heated funnel, agitated hopper and 14 filling heads with bending and welding claws. When processing metal tubes, the bending tools as well as the pressing tools have the task of welding the tube.

The welding of the end of the tube (in the case of double or triple folds) is carried out using the folding tools, by bending the compressed end of the tube. In the additional folding station in the case of a saddle fold, an additional fold is carried out. In the pressing and stamping station, the fold is compressed and, if necessary, an embossed stamp can be applied. The standard fold width is 5 mm.

Formats currently available for tube diam. 32 mm and tube diam. 39 mm.

Machine location

Open on Google Maps- Address Via Don L. Guanella 1/E

- City Bologna

- Zip/Postal code 40141

- Country Italy