Details

Updated on November 3, 2023 at 5:30 pm-

Machine ID:

ML-23952 -

Category:

Packaging equipment - Machine type:

Packaging Line for Ampoules - Manufacturer:

MARCHESINI - Model:

FARCON COMPLETE LINE -

Year of manufacture:

2002 -

Condition:

Used - Detailed condition:

As good as new (ex-display) - Rental?:

No

Description

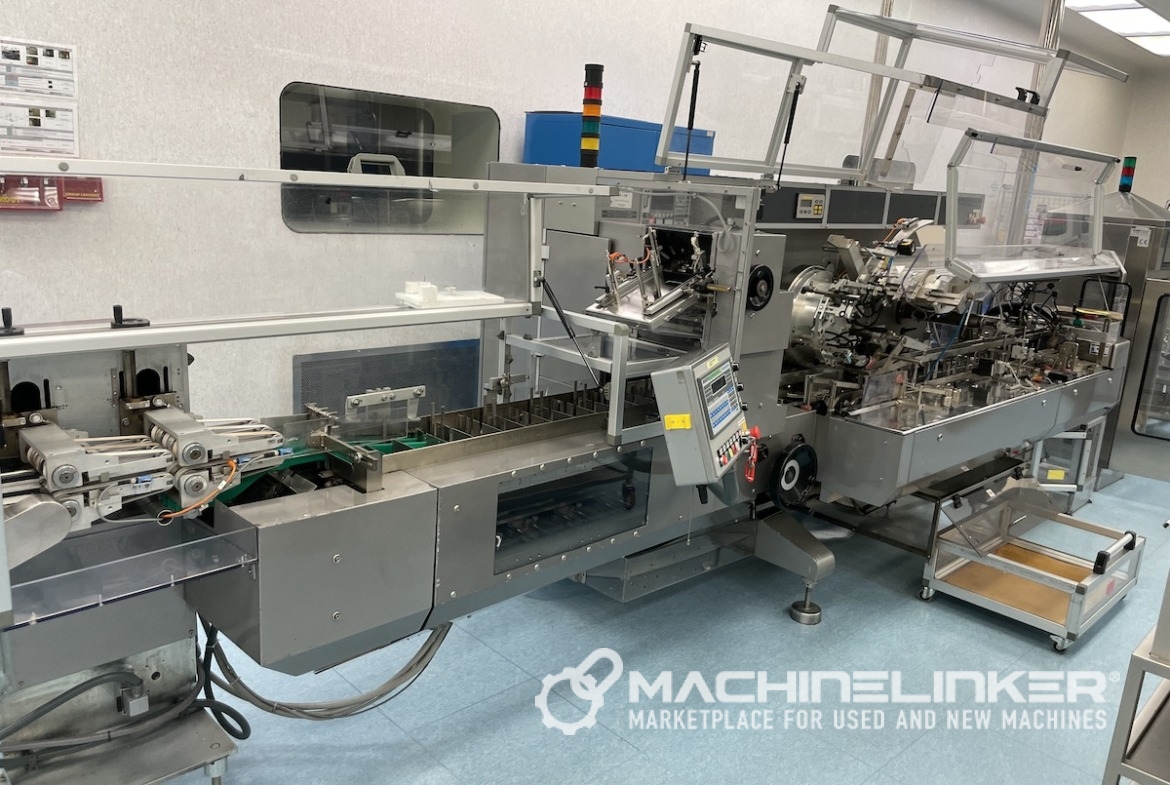

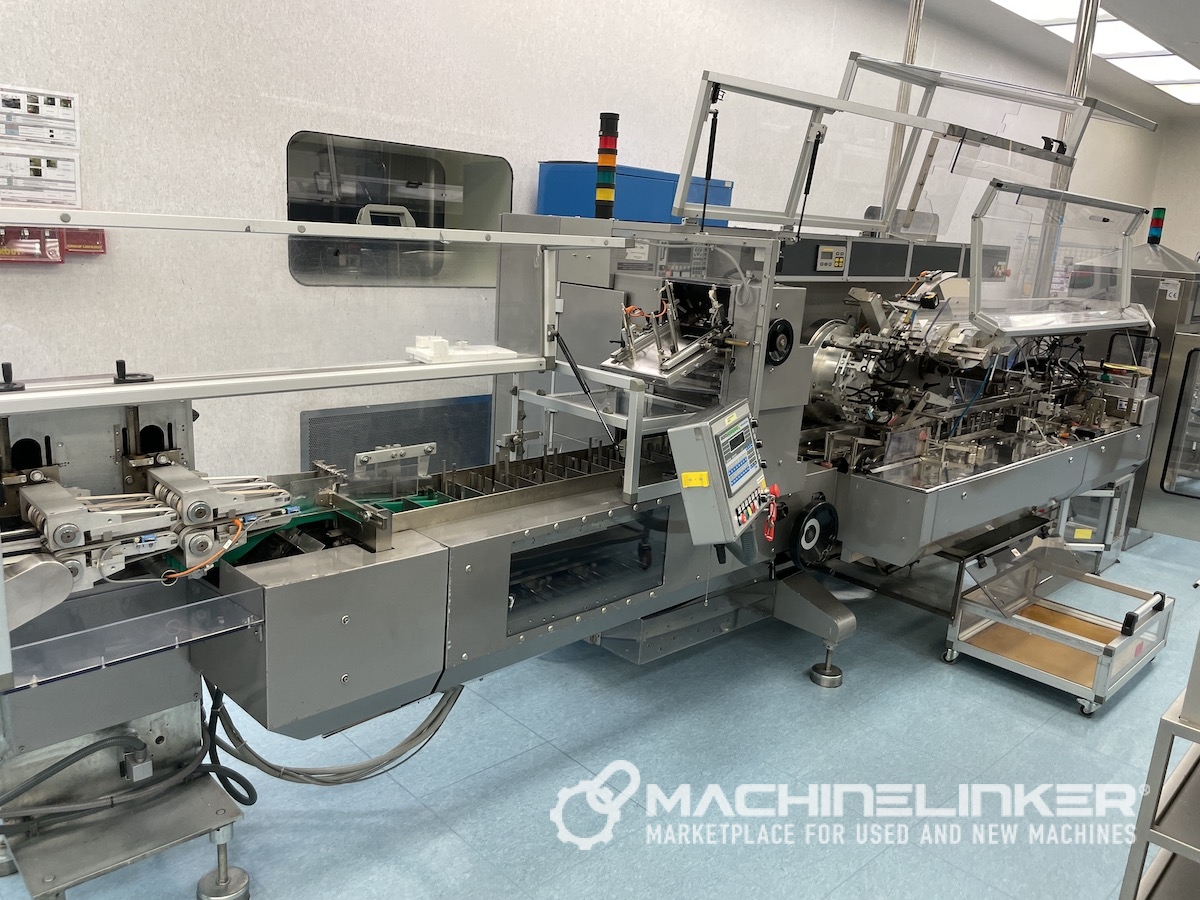

BLISTER MACHINE FOR AMPOULES FARCON FC320 WITH VISION SYSTEM SEA VISION

For thermoforming trays for ampoules, vials.

Manufacturer: Farcon (MARCHESINI GROUP)

Model: FC320

Year: 2002

Automomatic ampoules feeder on trays

Pick and place system to pick up trays and place them on a conveyor

Two-way conveyor

Maximum forming depth: 42 mm

Speed: 45 cycles/min

Maximum forming area: Film width 254 mm; Film pitch 220 mm

Maximum cutting area: Film width 248 mm; Film pitch 210 mm

Maximum production: 63000 ampoules (1 ml)/h

Hydraulic network:

– Pressure : 1.5 to 2 bars

– Connection : Ø 1/2” Gas

– Temperature : 11°C to 15°C

– Average consumption : 200 l/h

Pneumatic network:

– Pressure: 6 to 8 bar

– Connection: Ø 3/4”

– Consumption: 500 Nl/min

Power supply: 400V 3-phase, 50Hz, 3A

Power: 6kVA

CARTONER CAM MODEL HV2 FOR AMPOULES

Model: HV2

Year: 2002

GUK leaflet folder

Laetus Argus 4 bar code reader

Material of machinable cases:

Compact carton with a weight of 220 +/- 400 gr / m2

Cords and preattached cases

Closure: With hot melt

Automatic ampoules trays feeder.

Electrical Trifase altering 220 or 380 V 50Hz

Motor power 3 Kw

Motor power bovine pump 1.25 Kw

Power transformer and service circuits 0.95 Kw

Total power 5.20 Kw

Air consumption: 17NL per minute at a pressure of 6 bar

CHECK WEIGHER INLINE PRODUCER RAMSEY TECNO EUROPA

Year: 2000

Belt with air reject system

Complete with control panel

Includes gripper belts at feed

WRAPPING MACHINE PRB MARCHESINI FAR 2001

Year: 2004

Long dual side pvc belt conveyor pushing station wrapping station sealing station folding station driven by variable speed

Pack dimensions:

Length: min. 60 mm – max. 210 mm

Width min. 60 mm – max. 250 mm

Height: min. 10 mm – max. 150 mm

Maximum output: 80 packs/minute

Power: 2,5 kw

CASE PACKER PRB MARCHESINI MODEL SP

Year: 2004

Automatic Horizontal Case Packer, machine for the final packaging in cardboard, built to ensure reliability, versatility and space saving. A really small size equipment with high production features. Automatic unit, able to perform automatically and in a continuous cycle the grouping of products, their introduction into shipping cartons previously taken from stock, formed and positioned in such a way as to enable the mobile hopper and the pusher to carry out the filling, which completed the two groups of transport side, which serve to maintain the correct squaring, convey the same to the exit by passing it through the operating groups which carry out the closure on both sides by tape closing.

Production: 12 cycles/min

Carton size range: min (AxBxC) 20x10x75; max 550x130x290

Case formats min-max (LxWxH): 200x120x100 mm; 550x350x350 (600) mm

TECHNICAL DATA

Power absorbed: Kw 3,18

Electric Frequency: Hz 50

Voltage: Volt 380

Pressure: bar 6

This unit can be easily changed over for different types of products including boxes, bottles, tubs and containers, and different size boxes.

The entire machine is equipped with safety sensors and plexi-glass safety doors.

Electrical panel with PLC.

Level control of boxes in stock, maximum load in power control, counters (packagings, working hours, etc.).

PALETTIZER PRB MARCHESINI MINISTRATUS

Model: Minustratus

Year: 2009

Format range A 150 – 600 mm B 100 – 400 mm C 80 – 610 mm

Pallet height: Standard dimension 1665

Pallet dimension: 800 x 1200 / 1000 x 1200

Max speed: 10 cycles per minute

Air compress: 6 bar

Air consumption: 0,7 NL/ per cycle

Electrical details: 380-220V 50Hz

Power installed: 6 kW

Machine location

Open on Google Maps- Address Via Don L. Guanella, 1/E

- City Bologna

- Zip/Postal code 40141

- Country Italy