Video

Details

Updated on June 24, 2024 at 7:37 am-

Machine ID:

ML-26529 -

Category:

Blister packaging machines - Machine type:

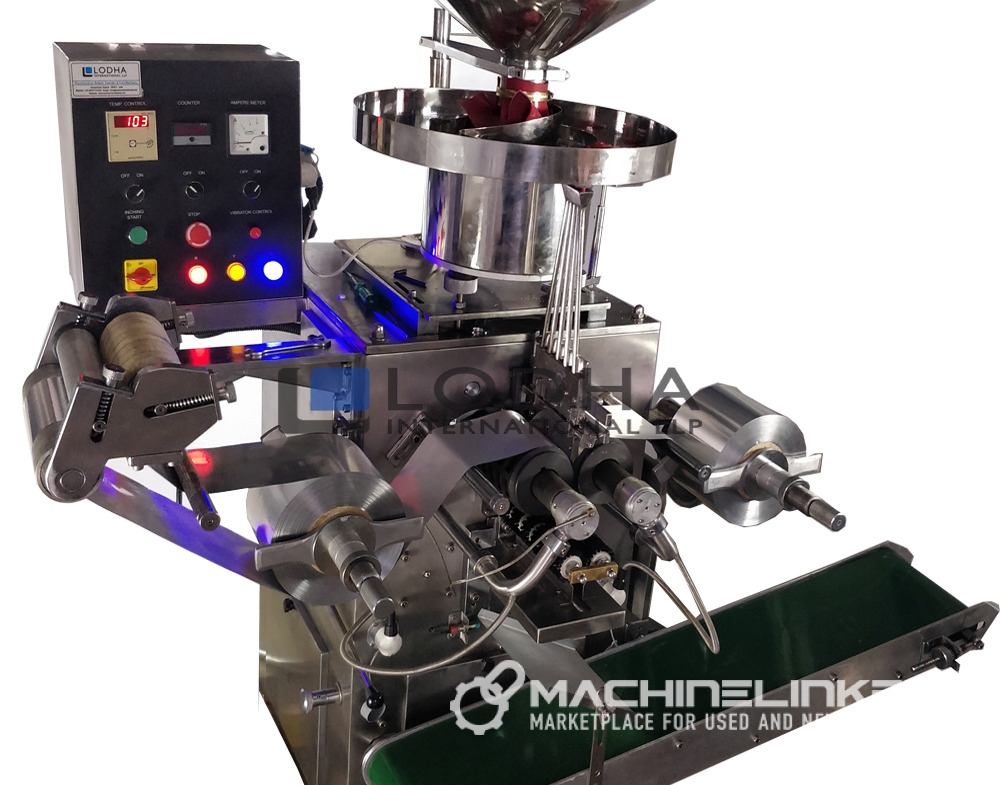

Automatic Strip Packing Machine - Manufacturer:

LODHA - Model:

LI-ST 4 -

Year of manufacture:

2024 -

Condition:

New - Detailed condition:

Brand-new (new) - Rental?:

No - Capacity:

36000 to 48000 - Electric Motor:

0.75 HP, 3 phase, 440V, 1440 RPM/TEFC (“REMI/HINDUSTAN” make) - Gear Box:

14:1 ratio, universal mounting type (“BONFIGLIOLI ”make) - Power Supply :

3 Phase - Machine Dimension:

1100 mm x 1050 mm x 1650 mm - Gross Weight:

620 kgs.

Description

Key Features of the Tablet Capsule Strip Packing Machine: All four processes—feeding, sealing, slitting, and cutting—are carried out automatically. Consequently, it is very efficient, which means that production costs are reduced as a result of lower labor costs.

Transfer strips from various-sized take-off conveyors to the packaging and inspection table.

Designed to fit a variety of body types and dimensions.

Various heat-sealed packing laminates can be processed using this machine.

Temperature regulation by digital means.

PLC Panel for control (Possible)

Adhering to cGMP norms.

The replacement components are simple to install.

Process Flow Diagram:

The product is transported to the chute by the vibrating feeder, which takes the supply tablets.

Chute: This device centers the pieces so they can enter the sealing roller by gripping them individually.

The adoption of a precise temperature control system allows the sealing roller to keep its temperature consistently high.

Slitting: The slitting’s position and column number can be readily changed.

Use the drawing brushes to tense the strip for flawless sealing and cutting.

Adjust the number of rows of cutting according to your needs with the cutter.

Strip Packing Machine Technical Specifications:

Models Available Model: LI-ST 4 Track 6 Track 8 Track 10 Track 12 Track Foil Width 145 mm 210 mm 260 mm 280 mm 310 mm Output/Min 600-1200 1200- 1800 1800-2500 2250 – 3125 2700–3750Machine location

Open on Google Maps- Address 98, Gajanan Industrial Hub -2 Behind Matrix Plaza, GIDC VATVA, Vinzol, Ahmedabad, Gujarat 382445

- City Ahmedabad

- Zip/Postal code 382445

- Country India