Video

Details

Updated on December 9, 2021 at 1:51 pm-

Machine ID:

ML-18636 -

Category:

Packaging equipment - Machine type:

Packaging Machine - Manufacturer:

LODHA - Model:

Automatic PVC ALU Blister Packing Machine -

Year of manufacture:

2021 -

Condition:

New - Detailed condition:

Brand-new (new) - Rental?:

No

Description

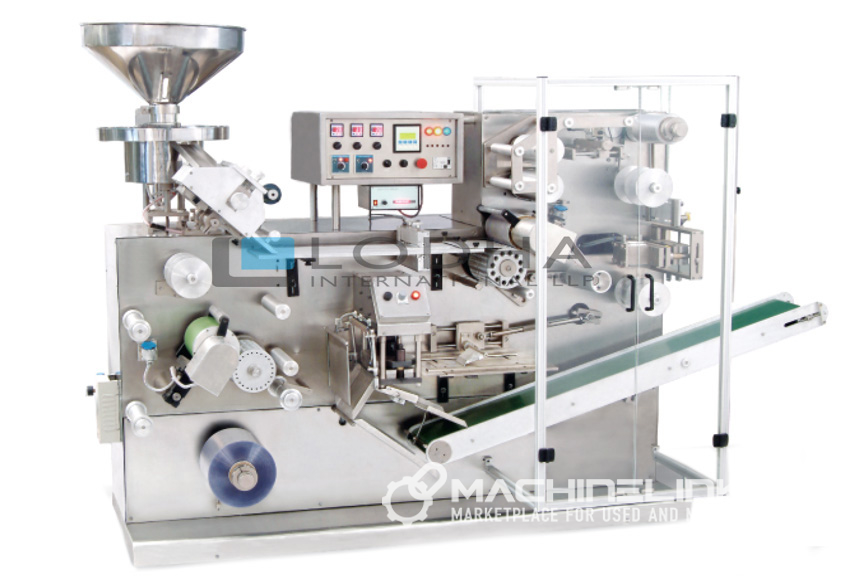

LODHA brings you comprehensive range of high-speed PVC-ALU blister packing machine. Our automatic blister packaging machine utilized for packaging of the tablets, capsules in a blister pack. Our world class quality, reliability, performance and cost-effective range makes our machines ideal choice for pharmaceutical industry of any size.

Process Operation:

Stainless steel cladding conforming to cGMP standards. Recipe Program through Man- Machine Interface LI-PA240 is a machine model with continuous operations of forming station, feeding station, sealing station and printing station. Whereas punching station is of intermittent nature. Product capacity of the machine depends on the product characteristics, pack layout and on type of feeding device. PVC film is generally used as base film and Aluminium foil with heat sealable VMCH coating as lidding film. Batch code printer, Inspection Camera and Inline perforator are the accessories, which can be mounted on the machine. The blister cavities are formed on the PVC/PVDC film web by vacuum processes. This blister formed web moves over the web guide track and at this station the products are fed into the individual cavities. The formed web along with the tablet or capsules moves towards a sealing station, where it is fused to the aluminium foil, which is drawn from an aluminium reel – feed station. The punching tool punches out the specified pack, which is transferred to the out-feed conveyor. Products to be packed on the machine are specifically pharmaceutical products such as Tablets and Capsules. Different type of products can be fed into the blister formed cavities on the formed web over the web guide track at the feeding zone. Separate Embossing or Perforation Station Stainless steel cladding conforming to cGMP standards. Recipe Program through Man- Machine Interface LI-PA240 is a machine model with continuous operations of forming station, feeding station, sealing station and printing station. Whereas punching station is of intermittent nature. Product capacity of the machine depends on the product characteristics, pack layout and on type of feeding device. PVC film is generally used as base film and Aluminium foil with heat sealable VMCH coating as lidding film. Batch code printer, Inspection Camera and Inline perforator are the accessories, which can be mounted on the machine. The blister cavities are formed on the PVC/PVDC film web by vacuum processes. This blister formed web moves over the web guide track and at this station the products are fed into the individual cavities. The formed web along with the tablet or capsules moves towards a sealing station, where it is fused to the aluminium foil, which is drawn from an aluminium reel – feed station. The punching tool punches out the specified pack, which is transferred to the out-feed conveyor. Products to be packed on the machine are specifically pharmaceutical products such as Tablets and Capsules. Different type of products can be fed into the blister formed cavities on the formed web over the web guide track at the feeding zone. Separate Embossing or Perforation StationOptional Features:

Batch code letter embossing attachment No fills detection and rejection system Print registration control for PACK TO PRINT Poly – carbonate guardUtilities Requirement:

Compressed Air: 14 CFM dry air having minimum pressure 6 kgs /cm. sq. Water Cooler: 7-9 Litres / Minute at min. Capacity 1200 K.cal / hour. Electrical Power: 7.5 KW, 380 – 415. AC, 50 hz, 3 Phase + N+E. Earthing Cable: Copper, 2.5 mm2 (Minimum)Technical Specification:

Model No. LI-PA 240 PVC Base Film Width Max 210 mm PVC Film Thickness Max 0.25 – 0.40 mm Sealing Foil Width Max. 206 mm Sealing Foil Thickness Max. 0.02 – 0.04 mm Pack Length 200 mm Pack Width 100 mm Forming Depth 16 mm Max. Out Put *4.5-5.5 meters/min (240 Blisters/ Min) Overall Dimensions L: 3100 W: 1100 H: 2000 mmMachine location

Open on Google Maps- Address 98, Gajanan Industrial Hub-2, Behind Matrix Plaza, GIDC Phase IV, Vinzol, Ahmedabad

- City Ahmedabad

- Country India

Contact seller

View machines

MachineLinker cannot be held responsible for the accuracy or reliability of information posted by sellers.