Details

Updated on November 19, 2021 at 2:56 pm-

Machine ID:

ML-18584 -

Category:

Other chemical-pharmaceutical equipment - Machine type:

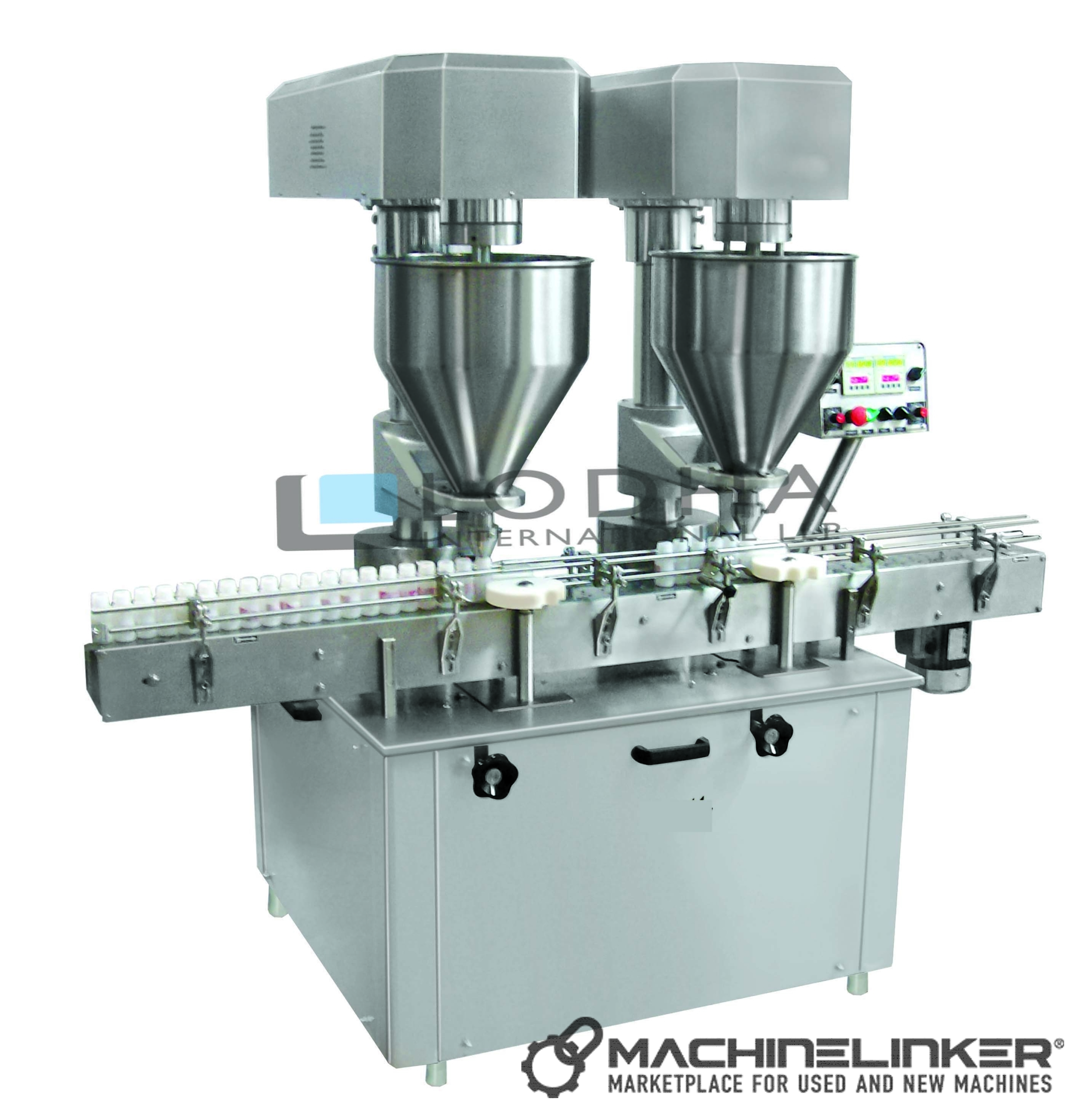

Filling Machine - Manufacturer:

LODHA - Model:

Automatic Auger Powder Filling Machine -

Year of manufacture:

2021 -

Condition:

New - Detailed condition:

Brand-new (new) - Rental?:

No

Description

Automatic Auger Dry Powder Filling Machine is suitable for Filling Dry Syrup, Powder and Granules in different type and shape of bottles with maximum speed up to 60 Bottles per minute depending on Fill Volume, type of Powder and Bottle Size using Single track twin hopper system. Machine with proven Augur type Powder Filling System for filling higher grammage of Powder in Single Dose. All Parts coming in contact with powder are made from SS316, Nylon and HDPE material. Machine with no change parts system for change in Size of Bottles due to pneumatically operated bottle separator system. Machine with built in Turn Table for Round Bottle at the infeed for continues feeding of bottles.

Special Features:

No Bottle – No Fill System All contact parts made of SS316 and Nylon/HDPE material with easy removal system for Cleaning Machine construction in SS304 material Variable Frequency Drive Speed Control Built in Turn Table at infeed side with Separate Drive for speed control Low Air – Machine Stop SystemHeavy Duty Mounting system for Filling Head for Trouble Free long-term operations

Process Operation:

The incoming dry bottle sterilized is fed through the in feed Turn Table with suitably guided on the moving Delran flat conveyor belt at the required speed for feeding. There is one filling head mounted on machine top plate in the same line. When bottle reaches to the first filling station, it will be held by the pneumatic bottle holder. Immediately it will be sensed by the bottle sensor as soon as it gets signals from sensor magnetic clutch starts to rotate which is mounted on auger shaft. It will fill the desired amount of powder to the bottle through auger, where rotation time is previously saved in PLC control. After filling of first bottle pneumatic piston goes back and release the first bottle to move on conveyor, by the same time second bottle also moves along with the first bottle in empty condition. The main advantage of this machine is Pneumatic bottle holding system is directly connected with Auger rotation, so till bottle get filled with powder as per set value pneumatic system will not going to release the bottle.

Technical Specification:

Model No.: LI-APF 1 LI-APF 2 Container Diameter 25mm to 85mm* 25mm to 85mm* Container Height 100mm* Maximum 100mm* Maximum Filling Range 5gms. To 60gms. In Single Dose System 5gms. To 60gms. In Single Dose System Accuracy +/- 2 to 3% Depending upon the Powder, under the controlled level of Humidity +/- 2 to 3% Depending upon the Powder, under the controlled level of Humidity Humidity Below 30% Rh required on machine to be arrange by customer Below 30% Rh required on machine to be arrange by customer Electrical 415VAC 3Phase and 220 VAC Single Phase Power Supply (50 Hz) with A.C. Drive 415VAC 3Phase and 220 VAC Single Phase Power Supply (50 Hz) with A.C. Drive Power 2.0 H.P. 4.0 H.P. Conveyor Height 815-940 mm adjustable 815-940 mm adjustable Overall Dimensions 1810 mm (L) x 905 mm (W) x 1900 mm 3800 mm (L) x 1500 mm (W) x 1900 mm Production Output Max. 30 bottles per min Max. 60 Bottles per minuteMachine location

Open on Google Maps- Address 98, Gajanan industrial Hub-2, Behind Matrix Plaza, GIDC Phase IV, Vinzol, Ahmedabad, India

- City Ahmedabad

- Country India