Video

Details

Updated on November 19, 2021 at 11:30 am-

Machine ID:

ML-18522 -

Category:

Other chemical-pharmaceutical equipment - Machine type:

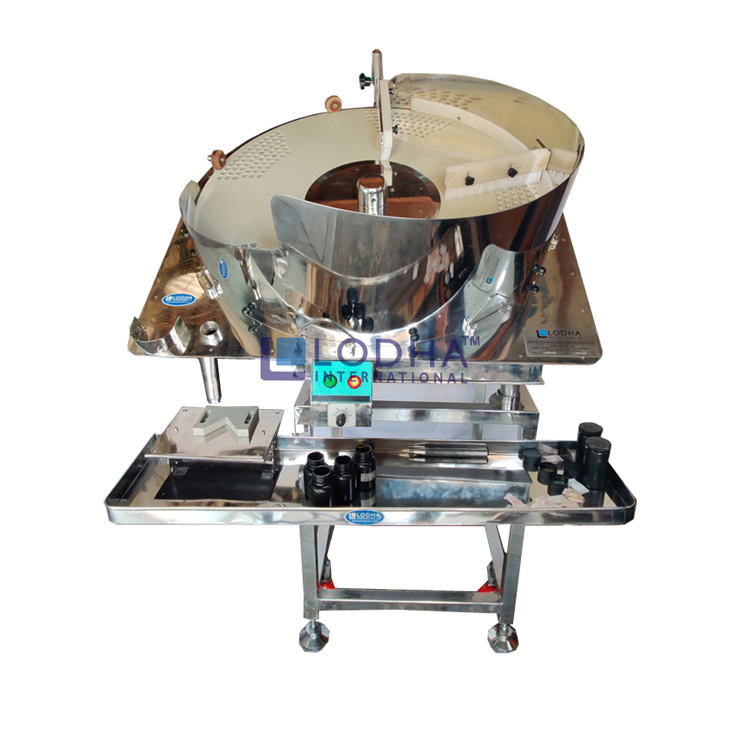

Counting and Filling Machine - Manufacturer:

LODHA - Model:

Semi Automatic Tablet/Capsule Counting & Filling Machine -

Year of manufacture:

2021 -

Condition:

New - Detailed condition:

Brand-new (new) - Rental?:

No

Description

Tablet Capsule Counting & Filling Machine is suitable for plastic and glass bottles. It is widely applied in Pharmaceutical, Nutraceutical’s, Cosmetics, Herbal and Ayurvedic industries.

Our Tablet Capsule counting & filling machine models range includes up to 150 tablets/capsules per min in glass bottles and rigid containers in bulk quantities and also where you need peak output. These exceptional machines are versatile enough to count coated/uncoated tablets, hard or soft gelatin capsules of any shape and size such as pearls, oblong and round.

Unique Features:

Adjustable Filler: The filler height can be adjusted up to 125mm for different height of bottles. All contact parts are fabricated out of stainless steel 316.

Gear Box and Drive:The heart of every machine is a heavy-duty Gear Box 40:1 ratio connected to a 3 phase AC 1 H.P. Motor 1440 RPM with variable speed drive. The RPM of the disc varies from 3 to 8 depending upon the product.

Delivery Chutes:Delivery Chutes direct the product from the counting disc into Bottles through the tray and chute. For accurate filling, tubes and adaptors of various sizes are supplied to suit different containers. Special delivery chutes will be supplied for counting and filling capsules in narrow mouth container such as vials.

Dust Removing Vacuum System: Integrated with the filler, under the hopper is the vacuum system that provides a dust free passage of stocks to the containers. The system also gives efficient and smooth running of the disc when uncoated tablets are counted.

Large Counting Discs:A 48″ diameter disc on single fill model gives every machine the highest capacity. Each disc is custom designed and manufactured to meet your individual filling requirements. These exceptional machines are versatile enough to count coated/uncoated tablets, hard or soft gelatin capsules of any shape and size such as pearls, oblong and round, efficient and smooth running of the disc when uncoated tablets are counted.

Operation:

The operation is completely automatic, after the basic setup. The operator has to only replenish tablets or capsules whenever required. The operations are controlled by the electrical switches provided.

Changing over:

Feed disc need to be changed to suit the shape and size of the product. Feed disc can be ordered with different numbers and sizes of pocket and can be interchanged in 5 minutes.

Technical Specification:

Specification Semi-Automatic Tablet Size Any Size Capsule Sizes 00, 0, 1, 2, 3, 4 & 5 sizes Feeding of Capsules In Counting Disc Feeding of Bottles Manually by Hand Bottle Diameter Up to 150 mm Diameter of Unscrambler Available in 24”, 36” & 48” Size Diameter of Filler Available in 24”, 36” & 48” Size Production Output:

20 capsules

30 capsules

50 capsules

100 capsules

250 capsules

500 capsules

1000 capsules 30 bottles/min

20 to 30 bottles/min

20 bottles/min

15 to 20 bottles/min

10 to 15 bottles/min

5 to 10 bottles/min

5 bottles/min. Power Consumption 1 H.P. Speed Control Through VFD Power Voltage 440 Volts, 3 Phase 50 Hertz, Motor-1440 RPM Feed Disc UHMW/Cast Nylon/Bakelite Diameter of Counting Disc 910 mm Overall Dimension 1345mm (L) X 1170mm (W) 990mm (H)approx. Net Weight 200 Kgs. approx. Gross Weight 350 Kgs. approx.

Machine location

Open on Google Maps- Address 98, Gajanan industrial Hub-2, Behind Matrix Plaza, GIDC Phase IV, Vinzol, Ahmedabad, India

- City Ahmedabad

- Country India