Details

Updated on May 22, 2024 at 3:52 pm-

Machine ID:

ML-26012 -

Category:

Packaging equipment - Machine type:

Autoclave - Manufacturer:

FEDEGARI - Model:

FXOAF6/CO40 -

Year of manufacture:

2016 -

Condition:

Used - Detailed condition:

As good as new (ex-display) - Rental?:

No

Description

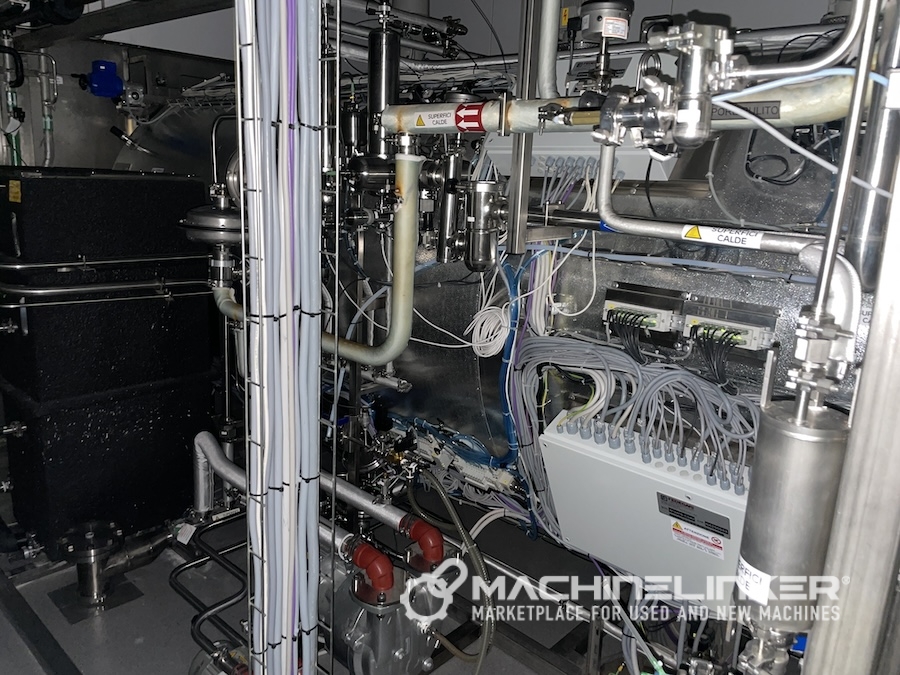

Specifications:

Indicative thermal dissipation, doors closed: side 1 – 0.9 kW, side 2 – 0.9 kA,

Maximum operating pressure: 3 bar g

Approximate weight of empty autoclave 5000 kg

Power supply 400 V 50 Hz, 19 kW

Pressure (bar g) Flow rate size

P1 water recovery from chiller 1,5 120 l/min 34.8×1.65

P1 water from chiller for exchanger 2 120 l/min 34.8×1.65

G water for empty pump 2 20 l/min 15.75×1.65

E1 industrial steam for gap 3 250 kg/h 22.1×1,65

E1 saturated steam ( 95-97%) 3,5 800 kg/h 47.5×1,65

D1 oiled compressed area for tools 5,5 100 NL/min 9.4×1.65

D oiled compressed area for chamber3,5 300 NL/min 34.8×1.65

A general discharge 72.9×165

FIELDS OF APPLICATION

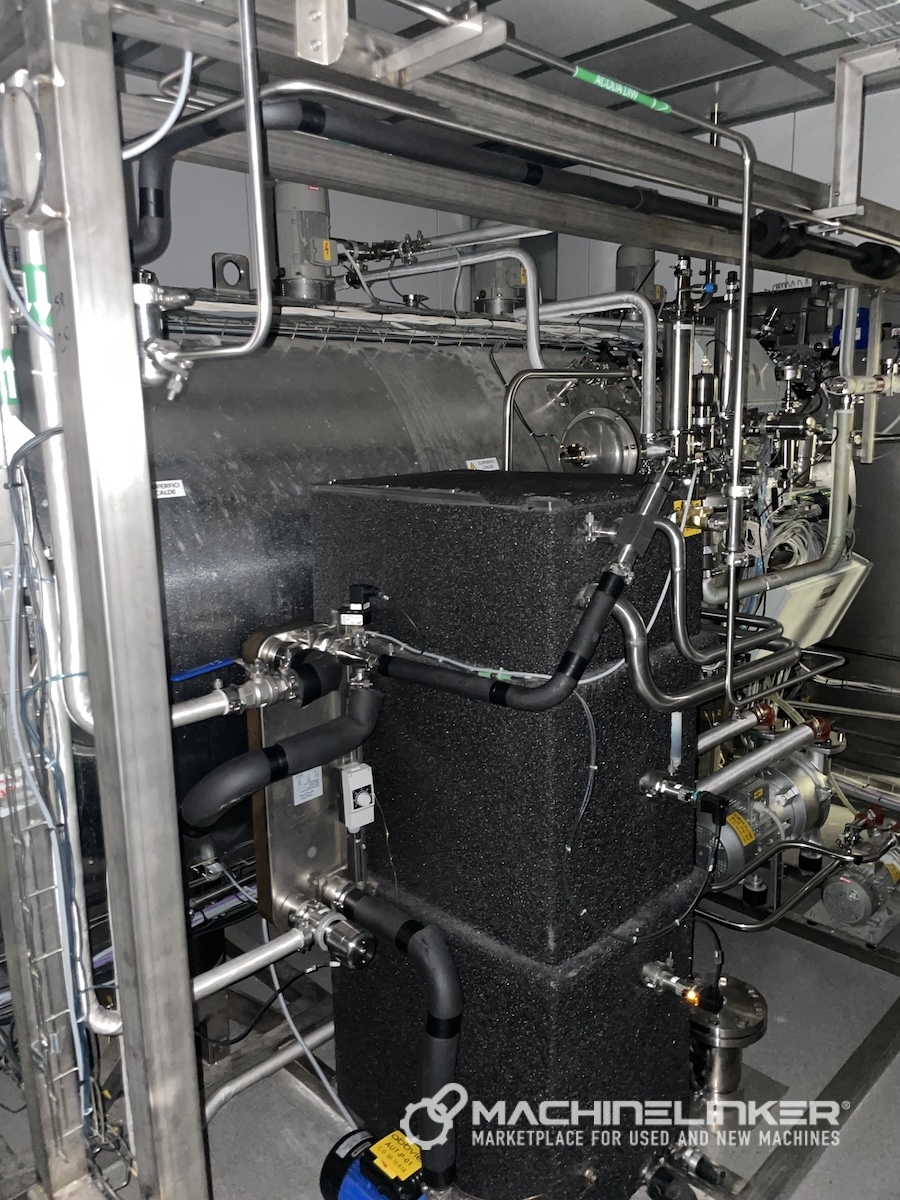

The FOA air-steam mixture sterilizer is suitable for:

– Sterilization of parenteral solutions, liquids in closed non-deformable containers (e.g., glass tubes) and liquids in closed deformable containers (e.g., plastic bags or bottles).

– Terminal sterilization of pre-filled syringes.

Sterilization of aqueous solutions in sealed containers (such as LVPs, vials, PFS, blister packs, etc.) turns out to be critical for a very specific reason: the pressure inside the primary container is higher than the saturated vapor pressure outside and at the same temperature. This could affect the product and/or the container itself, with the risk of deformation.

Hence our unique approach to back pressure sterilization:

– Flexibility: control of critical process parameters to ensure maximum flexibility of the sterilization cycle and avoid unwanted container deformation/damage by applying the most appropriate heat treatment to the product.

– Total control: total temperature and pressure (steam + air) control. A flow diverter and one or more fans ensure uniform diffusion of the mixture.

– Process optimization: The load comes out dry and ready to use.

– Integration & validation: pre-validated and standardized Thema process controller for all our machines.

– Internal chamber surface is mechanically polished with a roughness of less than Ra <0.4 μm.

– 2 doors, automatic sliding, to best optimize the available space.

– 5 RTD PT100 probes for temperature control in the chamber and in the product (3 flexible + 2 fixed).

-Automatic air filter sterilization complete with fixed thermo-probe in the filter bell to monitor the temperature inside the filter.

– 2 passages for validation sensors.

– Door sealing ensured by Fedegari’s unique and patented profile gasket.

– Exclusively patented gaskets from Fedegari that guarantee 100% door sealing. These gaskets are FDA compliant and additionally USP Class VI compliant.

– All stainless steel 316L- 1.4435 and 316L – 1.4404 plumbing system with exclusive quick connections and silicone gaskets.

– Equipped with one or more fans in relation to the chamber size, with patented magnetic drive ventilation system, without through-shaft in the chamber: ensures better sealing in the chamber, reduces maintenance frequency and does not require lubrication.

Machine location

Open on Google Maps- Address Via Don L. Guanella 1/E

- City Bologna

- Zip/Postal code 40141

- Country Italy